System description

Total capacity

Task

Solution

For the extraction of the light dust, a system has been established which is generally designed according to the piston-effect principle. The system and ventilation principle have been smoke tested and approved by the German product and certification organisation, TÜV. The system complies with applicable requirements and provides an optimal working environment and the best working conditions for production machines and personnel.

A ventilation unit has been installed to recover heat from the exhaust air to the supply air in order to save energy.

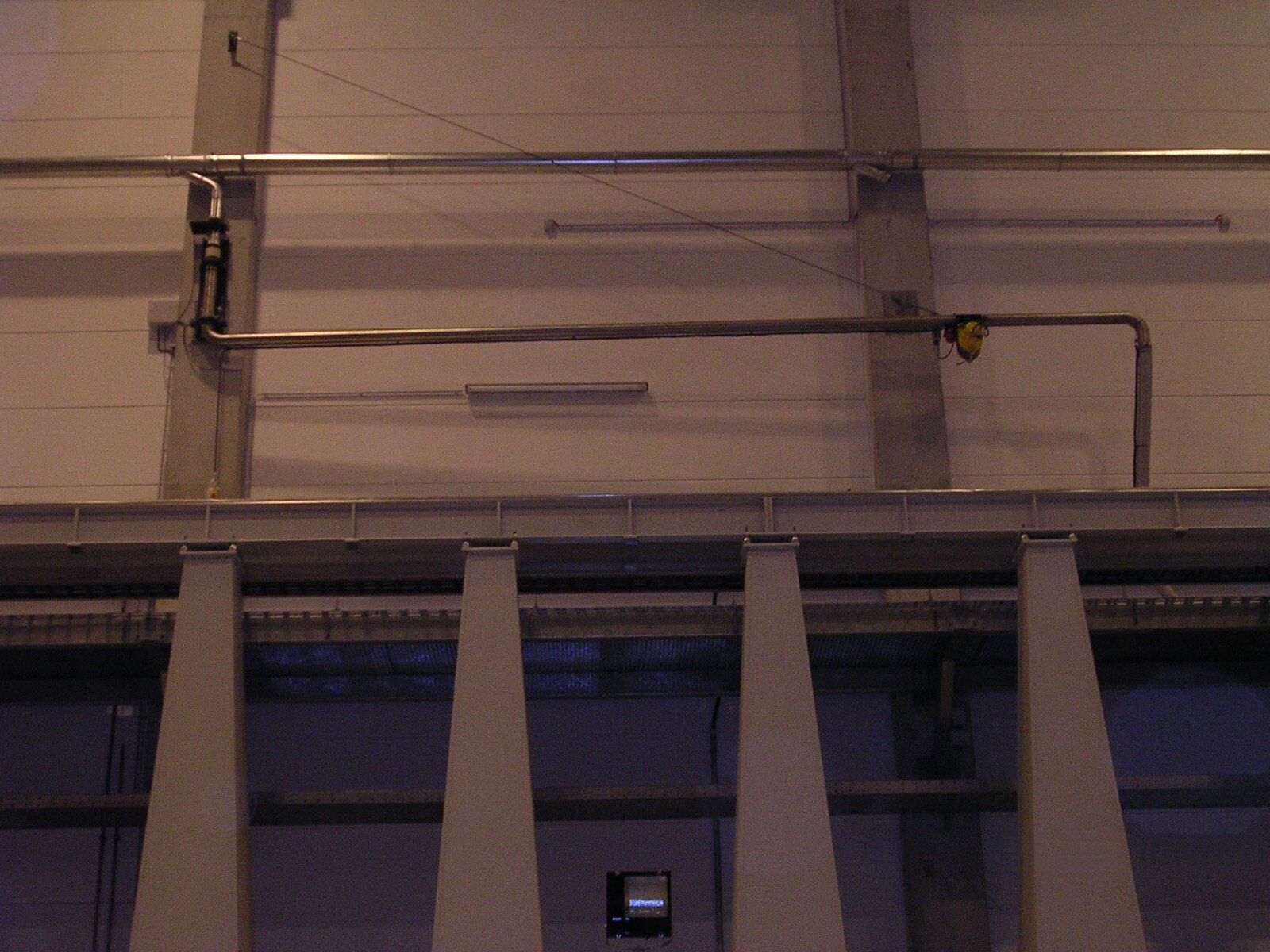

For the extraction of the heavier dust on the floor of the CNC machine, a vacuum cleaner system has been installed, which runs on high vacuum. Six metres of outriggers have been installed, on which hoses and cleaning equipment are mounted directly. Automatic start/stop of the system is provided via a signal switch on the cleaning equipment for optimal user-friendliness. The filter system ensures that the emission requirements for discharges are met.

The filter system is designed according to the ATEX directive, as the dust poses a potential explosion risk.