Ventilation solutions for the Mineral Industry

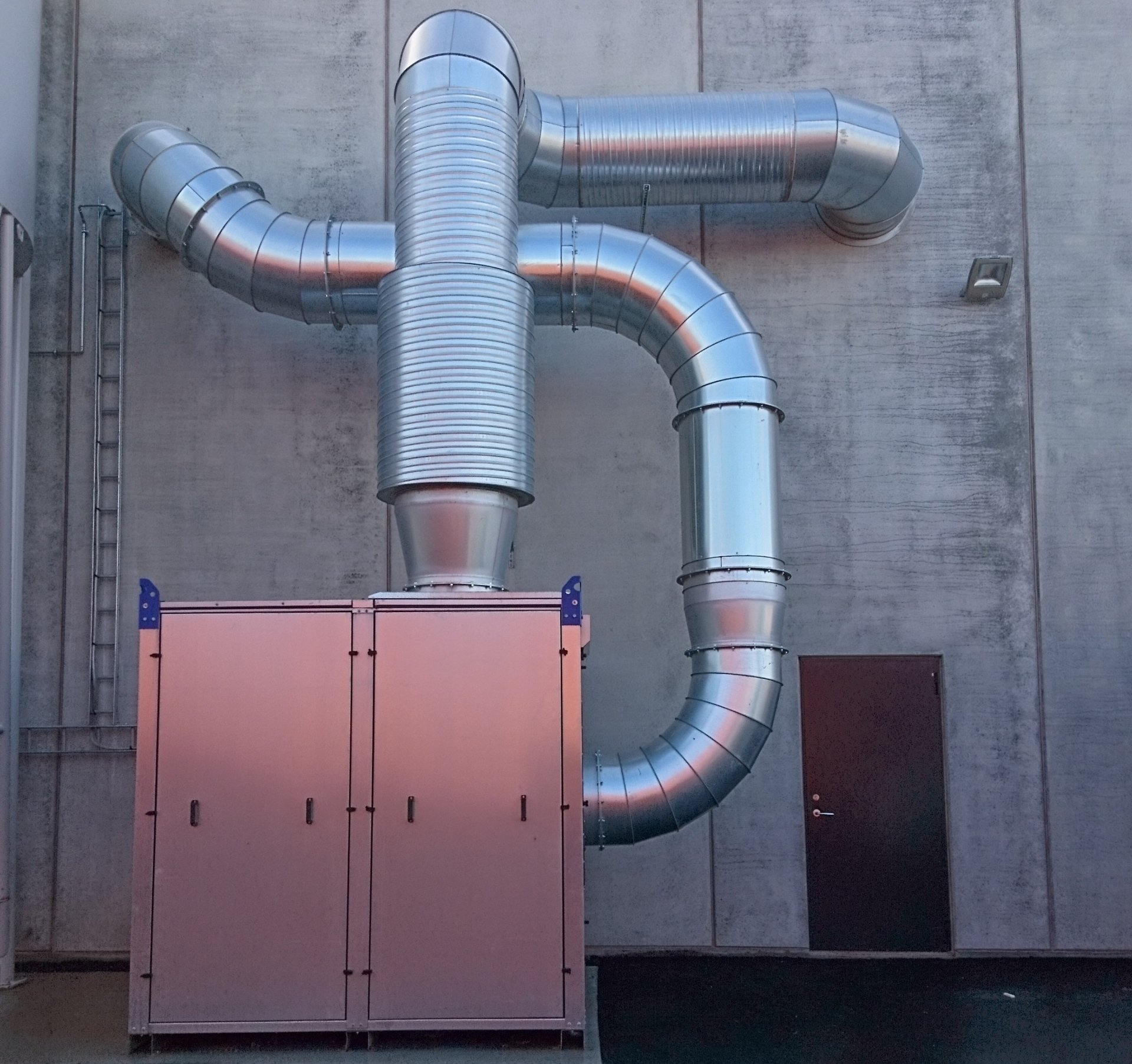

Robust extraction for the mineral and concrete industry

Protect employees and machinery from abrasive and harmful dust with Technor's robust solutions.

Processing stone, concrete, and asphalt generates fine dust that often contains harmful silica. Effective extraction is required to prevent serious health hazards and minimize wear on production equipment. Technor designs durable systems that capture dust directly at the source, ensuring a healthy and compliant working environment.

Stop the dangerous quartz dust

The authorities focus heavily on respirable crystalline silica (RCS), which is one of the biggest health risks in the industry. Removing the microscopic particles that penetrate deep into the lungs requires more than just a simple fan.

- Effective source extraction: We design enclosures and suction hoods that capture dust the moment the material is broken, mixed, or moved.

- Approved filtration: Our filters are classified to handle the finest particles, allowing air to be recirculated (where permitted) or discharged cleanly into the environment without disturbing neighbors.

- Compliance with limits: We help you document that the suction capacity is sufficient to keep you below applicable occupational exposure limits (OELs).

Durability that pays off

Mineral dust acts like sandpaper in piping systems and filters. An undersized system will quickly wear out from the inside, leading to holes, leaks, and expensive repairs.

- Heavy-duty materials: We use pipes and bends with thick wall gauges (and optionally wear linings) that can withstand abrasive materials.

- Correct air velocity: By carefully calculating the air velocity, we ensure that the dust remains suspended without unnecessarily "sandblasting" the pipes.

- Pre-separation: For large material volumes, we use cyclones to separate coarse material before it reaches the filter unit, significantly extending the lifespan of the filter cartridges.

Solutions that last

We have delivered extraction systems to some of the most demanding production environments. Here are three examples of how we handle minerals and concrete:

Rockwool A/S

The production of stone wool involves high temperatures and fiber-rich dust, which must be handled safely for both the environment and employees.

Randers Tegl A/S

At the brickworks in Hammershøj, handling clay, sand, and finished bricks creates significant dust that can negatively impact the working environment.

Damolin (Fur)

Damolin mines and processes moler (diatomaceous earth) for products like cat litter and absorbents. The process of handling this lightweight but dusty natural material requires effective filtration.

Operational reliability under harsh conditions

Your production doesn't stop because it's dusty. Neither should the extraction system. Our systems are built to run 24/7 in aggressive environments with large temperature fluctuations and varying loads

.

- Automatic cleaning: Our filters are cleaned automatically during operation via compressed air pulses (pulse-jet), ensuring constant, stable suction without manual stops.

- Service-friendly design: Although the systems are robust, they are designed for easy service, allowing wear parts to be changed quickly and efficiently.

Do you have problems with dust and wear?

We have experience with everything from fine cement and gypsum to coarse granite and insulation materials. Let us review your system and find a solution that lasts.

Contact us for a no-obligation talk about durable extraction.

Interested in collaborating? Contact us to learn more

If one or more of our ventilation solutions sound interesting to you, please contact us for a free, no-obligation chat about how we can solve your ventilation and extraction challenges. We have been doing this for the past 35 years, so we have the experience to take care of your needs.

Contact us by phone at 96682200, email technor@technor.dk, or use the contact form below - we will call you back as soon as possible.